17с-2-3

BuyProduction according to TR 2913-001-15365247-2004

Pipeline connection:

— threaded-end connection;

— flanged connection.

The connection is designed for loads from the valve weight and reactive forces appearing in case of the valve activation.

Installation position: vertically in the highest part of the site protected.

Climatic version: У, УХЛ, ХЛ, Т according to GOST 15150-69.

Placement category: 2, 3 according to GOST 15150-69.

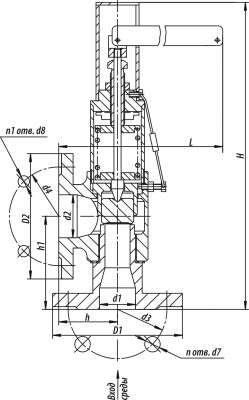

| d1, mm: | 40 |

| d2, mm: | 48 |

| D2, mm: | 140 |

| D1, mm: | 145 |

| L, mm: | 225 |

| H, mm: | 343 |

| h, mm: | 65 |

| DN, mm | PN, MPa | Tmax of the Medium, ºC | Body Material, Steel | Working Medium | Operating Stroke, mm | F, cm² | Adjustment Range of Рн Valve, MPa | μ, not less than | Inlet/Outlet Diameter, mm | d3, mm | d4, mm | d7, mm | d8, mm | n | h1, mm | n1 | Full Weight, kg |

| 40 | 1 | 250 | 20 | Пар | 8+1,5 | 6,1 | 0,6±0,15 | 0,7 | 40/50 | 110 | 110 | 18 | 14 | 4 | 100 | 4 | 7,8 |

| DN - Nominal Diameter PN - Nominal Pressure P - Pressure |

Tmax - Maximum Design Temperature Mкр - Spindle Torque t - Response time μ - Fluid Flow Coefficient |

h - Valve Stroke Kv - Throughput Capability F - Seat Area ζ - Resistance Coefficient |

The direct-acting pressure safety valves are intended for the equipment protection against overpressure of the working medium higher than the allowed value.

The valve is closed in case of steam pressure reduction in the site protected up to a definite value of the working pressure.

The choice of the pressure safety valve from the product line, represented in the catalogue, is carried out depending

on the working medium parameters in the site protected

and the required throughput capability.

The quantity of the pressure safety valves and their throughput capability for general-purpose power supply plants shall be chosen as per calculation according to the Regulatory Technical Documentation agreed with the Federal Service for Environmental, Technological and Nuclear Supervision of the Russian Federation.

08:07

08:07