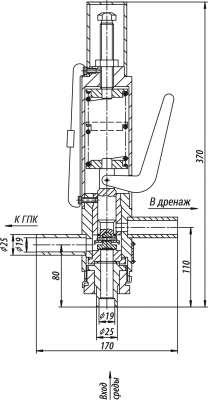

8c-3-1

BuyPipeline connection:

— pulse valves – welding-on;

— pressure safety valves – welding-on and flanged connection.

Installation position: with arrangement of the shutoff device axis to a true vertical in the highest part of the site protected.

Gate sealability: according to class А GOST 9544-2015.

Climatic version: У, УХЛ, Т according to GOST 15150-69.

Placement category: 3 according to GOST 15150-69.

| DN, mm | PN, MPa | Tmax of the Medium, ºC | Body Material, Steel | Working Medium | Operating Stroke, mm | Adjustment Range of Рн Valve, MPa | Inlet/Outlet Diameter, mm | Full Weight, kg |

| 20 | 4 | 450 | 20 | Пар | 3 | 0,25- 1,2 | 19/19 | 4,5 |

| DN - Nominal Diameter PN - Nominal Pressure P - Pressure |

Tmax - Maximum Design Temperature Mкр - Spindle Torque t - Response time μ - Fluid Flow Coefficient |

h - Valve Stroke Kv - Throughput Capability F - Seat Area ζ - Resistance Coefficient |

These safety devices are intended for provision of safe operation of the equipment and electric power plant systems by means of protection against overpressure of the working medium higher than the allowed value.

The safety devices are automatically activated and, when opening, they discharge the working medium surplus from the site protected into the atmosphere. The safety devices are represented by pilot-operated safety valves (POSV) composed of a pressure safety valve and a pulse valve.

According to GOST 356-80, the items designed for the ultimate pressure allow their application on operating parameters within the following range:

— at PN 10 MPa – from 10 MPa, 200 °С to 3,6 MPa, 455 °С;

— at PN 25 MPa – from 25 MPa, 200 °С to 9 MPa, 455 °С;

— at PN 6,3 MPa – from 6,3 MPa, 200 °С to 2,3 MPa, 455 °С.

The choice of the pulse and pressure safety valves, represented in our catalogue, is carried out depending on the working medium parameters and the required throughput capability.

The quantity of the pressure safety valves and their throughput capability for general-purpose power supply plants shall be chosen as per calculation according to the Regulatory Technical Documentation agreed with the Federal Service for Environmental, Technological and Nuclear Supervision of the Russian Federation.

The main pressure safety valves of medium and low pressure of series 7с, 111, 694 are intended for installation on the reduced steam pipelines, vessels and boilers. The main pressure safety valves of series 7с are completed with a pulse valve of series 8с and have a high-efficient flow path (BKZ Patent No. 2413111), enabling receipt of the required expenses at much lesser weight and size characteristics and, respectively, at almost twofold lesser cost.

Moreover, upon the customer's demand, it may be equipped with a special damping system, helping to change the valve closing speed for prevention from dynamic loads in the turbine bearings when installing the valves in the turbine shop (BKZ Patent No. 2285181). The main pressure safety valves of series 111, 694 are used with pulse valves of series 586 and 112 depending on the required medium parameters.

The main difference of high-pressure POSV of series 1202, 1203, 875, 392, 530 is provision with a pulse valve DN20 of series 586 with an electromagnetic actuator and a duplicating lever-operated one (ensuring activation in case of power failure). Such actuator is based on two electromagnets and one electromagnet of bilateral action, which provide high accuracy and timely opening and closing of the main pressure safety valve according to the pressures set at the electric-contact manometer.

The adjustment of the pulse valve in the duplicating mode on the actuation pressure is only carried out by means of choosing a place for weight installation on the lever.

11:16

11:16