935-100-0A

BuySwing check valves according to TR 3740-002-15365247-2004.

Structural designs: lifting and rotary valves.

Installation position of the check valve: only on horizontal pipeline sections with the medium flow direction “under the plate” so that the flow direction coincides with an arrow drawn on the body, provided that the nut (cover) is only directed upwards.

Installation position of the swing check valve: the swing check valves may be installed on horizontal sections with the cover upwards and on the vertical pipeline sections with the medium direction from the bottom upwards under the plate.

Pipeline connection: welded connection.

Gate sealability: according to class А GOST 9544-2015.

Climatic version: У, УХЛ, ХЛ, Т according to GOST 15150-69.

Placement category: 1, 2, 3 according to GOST 15150-69.

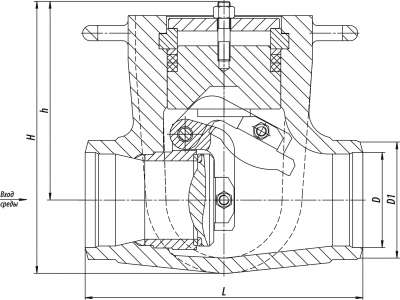

| D1, mm: | 146 |

| D, mm: | 109 |

| h, mm: | 375 |

| H, mm: | 500 |

| L, mm: | 400 |

| DN, mm | PN, MPa | Tmax of the Medium, ºC | Body Material, Steel | Working Medium | ζ, not more than | Full Weight, kg |

| 100 | 23,5* | 250 | 20 | Вода | 2,0 | 105 |

| DN - Nominal Diameter PN - Nominal Pressure P - Pressure |

Tmax - Maximum Design Temperature Mкр - Spindle Torque t - Response time μ - Fluid Flow Coefficient |

h - Valve Stroke Kv - Throughput Capability F - Seat Area ζ - Resistance Coefficient |

The check valves and swing check valves are used in the pipeline systems as uncontrolled, automatically operating protective devices, serving for prevention of a working medium reverse flow in emergency situations.

The check valve/swing check valve is open in working condition under the influence of the working medium flow. If there is no motion of the working medium or if the flow operates in the reversed direction, the check valve/swing check valve is closed.

According to GOST 356-80, the items designed for the ultimate pressure

allow their application on operating parameters within the following range:

— at PN 100 from 10 MPa, 200 С to 3,6 MPa, 455 С.

— at PN 63 from 6,3 MPa, 200 С to 2,3 MPa, 455 С.

05:56

05:56