950-200/250-Э

BuyPipeline connection: welded connection.

Maximum pressure differential on the valve: critical.

Installation position: on horizontal pipeline sections with the medium direction

to the rod through the lateral branch pipes.

Climatic version: У, УХЛ, ХЛ, Т according to GOST 15150-69.

Placement category: 2, 3 according to GOST 15150-69.

The valve control is carried out with the help of a multi-turn built-in electric

actuator.

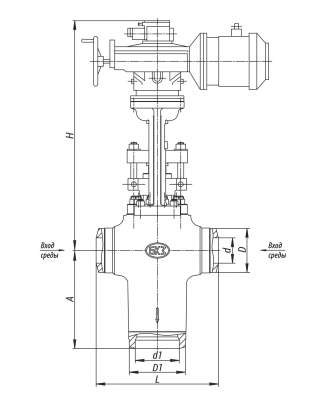

| H, mm: | 1485 |

| L, mm: | 850 |

| D1, mm: | 345 |

| D, mm: | 345 |

| d1, mm: | 251 |

| d, mm: | 208 |

| DN, mm | Рр, MPa | Tmax of the Medium, ºC | Body Material, Steel | Working Medium | Operating Stroke, mm | Max. Steam Flow at Critical Pressure Differential, t/h | TQ, N•m, maximum torque at spindle plug | Full Stroke Rotation Number | Designation of the electric drive | N, kW | t хода, с. | А, mm | Full Weight, kg |

| 200 | 25 | 545 | 15Х1М1ФЛ | пар | 80 | 1000 | 3096 | 8 | 797-ЭР-0 | 11,8 | 12 | 600 | 2361 |

| DN - Nominal Diameter PN - Nominal Pressure P - Pressure |

Tmax - Maximum Design Temperature Mкр - Spindle Torque t - Response time μ - Fluid Flow Coefficient |

h - Valve Stroke Kv - Throughput Capability F - Seat Area ζ - Resistance Coefficient |

The throttle globe valves of series 950 serve as controlled throttling devices of FRPRDS, which perform pressure throttling of the passed medium together with throttling devices sequentially installed after the valves.

They are intended for the live steam discharge in case of starting or stopping the power generating unit, in case of steam requirement per a turbine less than the evaporation capacity of the steam generator, excess steam pressure increase in the system and sudden reduction of the turbine load.

05:56

05:56