9с-5-2-2

BuyProduction according to TR 2913-001-15365247-2004

Installation place: as a rule, the valves are installed on the cooling water injection

pipelines in DS, PRDS, FRPRDS and industrial pipelines.

Installation requirements: the valves are designed for outdoor installation and in

closed premises with the ambient temperature up to +70 С.

The valves equipped with built-in actuators shall be only installed on horizontal

pipeline sections with the actuator position upwards.

Pipeline connection: welded connection.

Climatic version: У, УХЛ, ХЛ, Т according to GOST 15150-69.

Placement category: 1, 2, 3 according to GOST 15150-69.

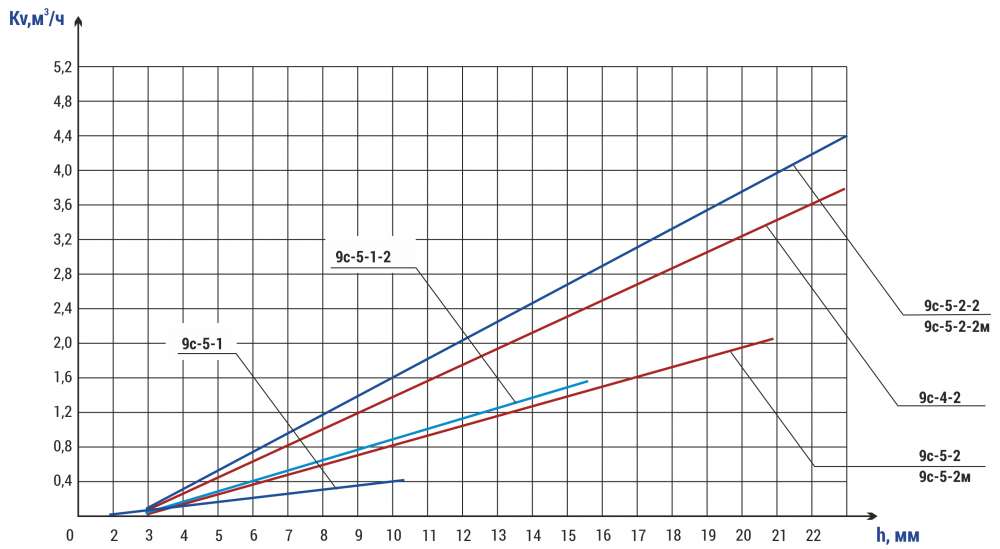

Depending on the lifting height of the valve needle, the throughput capability is

shown in the diagrams.

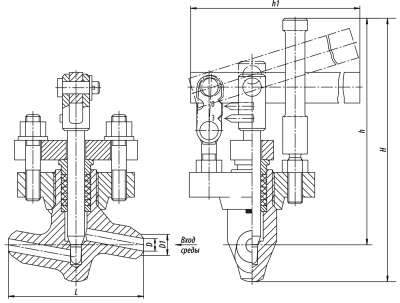

| L, mm: | 160 |

| H, mm: | 293 |

| h, mm: | 247 |

| D1, mm: | 32 |

| D, mm: | 22 |

| DN, mm | PN, MPa | Tmax of the Medium, ºC | Body Material, Steel | Working Medium | Operating Stroke, mm | Max. Kv, m³/h | Max. Pressure Differential, MPa | F, cm² | TQ, N•m, maximum torque at spindle plug | Designation of the electric drive | N, kW | t хода, с. | h1, mm | Weight without Electric Actuator, kg | Full Weight, kg |

| 20 | 10 | 350 | 20 | Вода-пар | 22 | 4,4 | 1,0 | 1,5 | 157 | МЭО-250/25-0,25У-99К | 0,25 | 10,0 | 300 | 6,2 | 34,0 |

| DN - Nominal Diameter PN - Nominal Pressure P - Pressure |

Tmax - Maximum Design Temperature Mкр - Spindle Torque t - Response time μ - Fluid Flow Coefficient |

h - Valve Stroke Kv - Throughput Capability F - Seat Area ζ - Resistance Coefficient |

The control needle valves are used as fluid flow regulators.

The provision of smooth control within the limits of the rated throughput

capability is achieved with the help of the valve needle form. The seat

has reinforced hard-facing of increased hardness which is resistant

to erosive and corrosive wear.

They are not used as shutoff devices.

According to the actuator type of the working body and control method, the

control needle valves are divided into the following types:

- Lever-operated control needle valves. The valve control is carried out on a

remote basis (automatically) with actuators of single-turn electric actuator type

(МЭО) through the lever. The allowed pressure differential on the valve shall not

exceed 1 MPa. - Control needle valves. The valve control is carried out with a handwheel or an

actuator with a current position sensor of electric multi-turn actuator types

(ПЭМ) (ABS ZEIM Automation), SAR (AUMA) or linear pneumatic actuators

FESTO, VALBIA, AIR Torque, ROTORK etc., chosen considering the working

medium pressure and air pressure. The valves equipped with actuators shall be

only installed on horizontal pipeline sections with the actuator position

upwards. - Control angle valves. The valves are controlled with a built-in multi-turn electric

actuator with a current position sensor of electric multi-turn actuator / electric

multi-turn mechanism types (ПЭМ/МЭМ) (ABS ZEIM Automation), SAR (AUMA)

etc. or linear pneumatic actuators of electric multi-turn actuator types (МЭП)

(ABS ZEIM Automation), REGADA etc., chosen considering the working medium

pressure.

According to GOST 356-80, the valves designed for the ultimate pressure allow

their application on operating parameters within the following range:

— at PN 100 MPa – from 10 MPa, 200 °С to 3,6 MPa, 455 °С;

— at PN 63 MPa – from 6,3 MPa, 200 °С to 2,3 MPa, 455 °С;

— at PN 25 MPa – from 25 MPa, 200 °С to 9 MPa, 455 °С.

08:09

08:09